Graphcore Uses TSMC 3D Chip Tech to Speed AI by 40%

U.K.-based AI computer company Graphcore made a significant boost to its computers’ performance without changing much of anything about its specialized AI processor cores. The secret was to use TSMC’s wafer-on-wafer 3D integration technology during manufacture to attach a power-delivery chip to Graphcore’s AI processor.

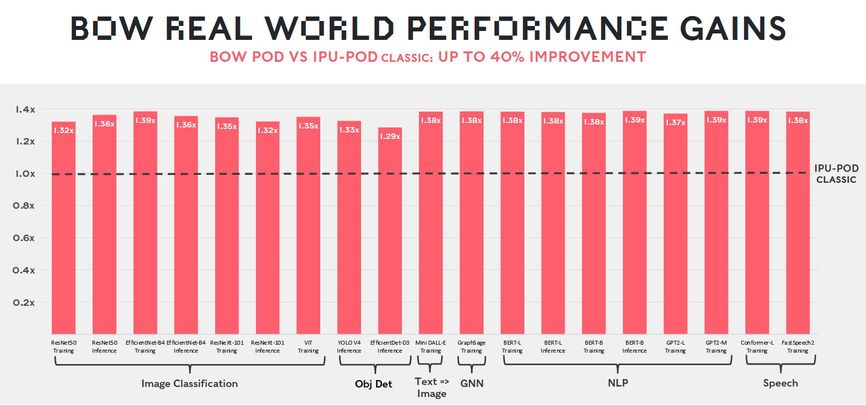

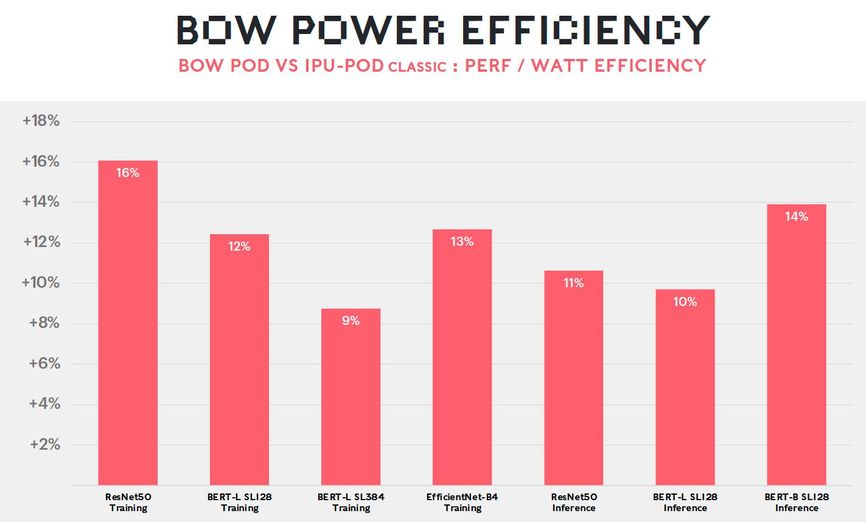

The new combined chip, called Bow, for a district in London, is the first on the market to use wafer-on-wafer bonding, say Graphcore executives. The addition of the power-delivery silicon means Bow can run faster—1.85 gigahertz versus 1.35 GHz—and at lower voltage than its predecessor. That translates to computers that train neural nets up to 40 percent faster with as much as 16 percent less energy compared to its previous generation. Importantly, users get this improvement with no change to their software at all.

“We are entering an era of advanced packaging in which multiple silicon die are going to be assembled together to supplement the performance advantages we can get from increasing progress along an ever-slowing Moore’s Law path,” says Simon Knowles, Graphcore chief technical officer and cofounder. Both Bow and its predecessor the Colossus MK2 were made using the same manufacturing technology, TSMC’s N7.

Compared with Graphcore’s previous generation, the new computers can train key neural networks about 40 percent faster.Graphcore

The new systems are up to 16 percent more efficient at training key neural networks.Graphcore

In other 3D-chip-stacking technology, such as Intel’s Foveros, already excised chips are attached to other chips or to wafers. In TSMC’s SoIC WoW technology, two entire wafers of chips are bonded. The chips on each have copper pads that match up when the wafers are aligned. When the two wafers are pressed together, the pads fuse. “You can think of this as a kind of cold weld between the pads,” says Knowles. The top wafer is then thinned down to just a few micrometers and the bonded wafer is diced up into chips. [READ MORE]